Mit gelebter Leidenschaft, einzigartiger Expertise und überzeugender Lösungskompetenz begeistern wir seit mehr als 130 Jahren unsere Kunden. Ganz gleich, für welche Produkte Sie eine geeignete Verpackungslösung brauchen, ganz gleich, welches Produkt Sie abfüllen wollen – IWK installiert Einzelmaschinen oder ganze

, die exakt auf Ihren Bedarf angepasst sind und verlässlich laufen – weltweit und rund um die Uhr! Dafür sorgt auch unser

(Technologien – Operativer Betrieb – Produktivität), der Sie im After-Sales durch Wartung, Upgrades oder Umbauten umfassend betreut.

Wir arbeiten branchenübergreifend. Unsere IWK-Systeme verpacken Produkte aus den Bereichen Pharma und Kosmetik, Medizintechnik / Medical Devices, Home Care, Lebensmittel und vielen weiteren Industrien. Wir wissen, worauf es ankommt, und stellen Ihnen unser breites Know-how gerne für das Füllen und Verpacken Ihres Produktes zur Verfügung. Unsere Verpackungsexperten freuen sich auf ein Gespräch mit Ihnen!

Jetzt Kontakt aufnehmen

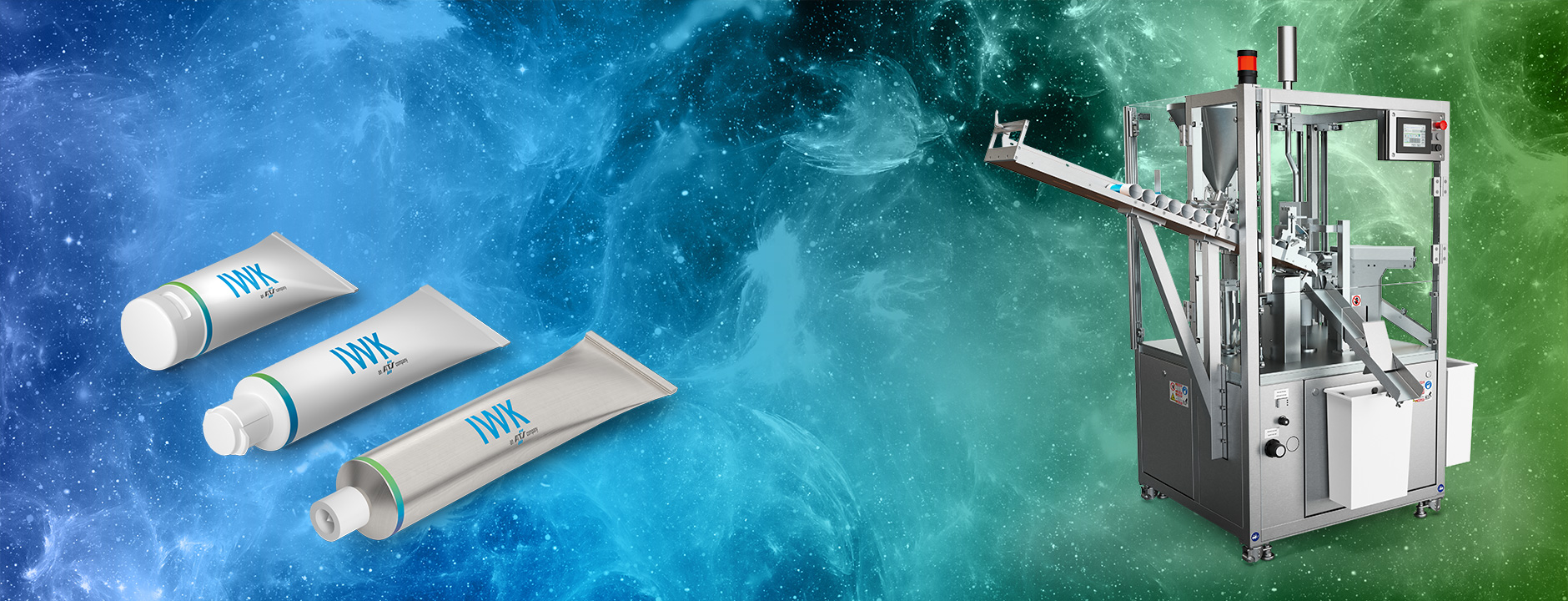

Sustainable Production mit IWK Tubenfüllmaschinen, Kartoniermaschinen und Verpackungsmaschinen

IWK steht für Spitzentechnologie und Linienintegrationskompetenz, für robuste Maschinen mit langen Laufzeiten und damit für Nachhaltigkeit und Zuverlässigkeit als

Tubenfüller und

Kartonierer. Was macht den Unterschied aus? Wir verkaufen nicht nur

Kartoniermaschinen,

Tubenfüllmaschinen und

Verpackungsmaschinen. Mit unserer Verpackungsentwicklung erarbeiten wir gemeinsam mit Ihnen Ihre Verpackungsidee zur Verpackung und dem passenden Verpackungssystem. Wir beraten bedarfsorientiert und mit Blick auf individuelle Anforderungen, passen unsere Maschinen kundenspezifisch an. Wir bleiben auch nach der Systemübergabe an Sie verlässlich an Ihrer Seite, damit Ihre Anlage reibungslos läuft. Weil unsere Maschinen hochwertig und langlebig sind, weil wir beim Betrieb auf Energieeffizienz und bei der Kartonage auf Nachhaltigkeit achten, steht der Name IWK für

Sustainable Production. Wir beeinflussen die CO

2-Bilanz unserer Kunden durch ausgereifte und verlässliche Technologien.

Kartoniermaschinen für jeden Bedarf

Ob vertikal oder horizontal –

IWK Kartoniermaschinen sind flexibel, erweiterbar und geeignet für unterschiedliche Verpackungsanwendungen wie Vialen, Ampullen, Flaschen, Tuben, Blister, Tiegel, Beutel, Buntstifte, Kaffeekapseln, Kugellager usw.

Formatwechsel lassen sich je nach Modell in Rekordzeit realisieren, sind leicht reproduzierbar, werkzeugfrei und teils automatisiert. Deshalb sind IWK

Kartoniermaschinen so vielfältig und variabel. Auch in punkto Reinigung und Bedienung bieten unsere

Kartonierer ein Höchstmaß an Komfort. Die Steuerung erfolgt über unser intuitives

HMI (Touchscreen Bedienfeld).

Die Kapazitäten unserer

Kartoniermaschinen liegen zwischen 20 FS/Min. und 1000 FS/Min. Die Auswahl der passenden Maschine erfolgt durch unsere Fachingenieure im engen Kontakt mit unseren Kunden, orientiert am geplanten Output.

Mehr als nur Kartonierer: Verpackungslösungen seit mehr als 130 Jahren

IWK steht seit Jahrzehnten für Innovation und Verlässlichkeit. Die

Historie des Unternehmens ist geprägt durch stetigen Fortschritt und beständige Weiterentwicklung. Wir sind mit den Anforderungen unserer Kunden gewachsen und unsere Kunden mit uns. Systemintegration und Mehrkomponenten-Verpackungen stehen auf unserer Agenda für das 21. Jahrhundert.

Individuelle Lösungen für individuelle Kundenansprüche

Wir haben unsere Maschinen beständig an neue Herausforderungen angepasst. Der Wandel und die Entwicklung unserer Kunden war und ist für uns stets Innovationsmotor. Individuelle Verpackungslösungen sind unsere Triebfedern. Deshalb steht am Beginn einer Zusammenarbeit stets die sorgfältige Analyse: Welchen Bedarf soll unsere

Tubenfüller oder

Kartonierer decken, sowohl was die Produktgestaltung, das Design als auch den Footprint und die Kostenstruktur angeht? Wir arbeiten termingerecht, kosteneffizient, zielorientiert und verlässlich.

Tubenfüll- und Kartoniermaschinen / Toploader für höchste Anforderungen

Ganz gleich welche Herausforderung uns unsere Kunden stellen – wir nehmen sie an. Unsere

Tubenfüller füllen zwischen 40 und 760 Tuben pro Minute. Ihre Variabilität ist ihre Stärke: Sie lassen sich für Kosmetika wie Zahnpasta oder Shampoo genauso einsetzen wie für Cremes und Salben aus dem Pharmabereich. Auch im Food-Bereich sind unsere

Tubenfüllmaschinen im Einsatz, zum Beispiel für Ketchup, Mayonnaise, Senf oder Margarine.

Auch Chemikalien wie Silikone lassen sich spielend auf unseren Anlagen abfüllen.

Variabel ist dabei auch das Tubenmaterial von Aluminium über Aluminium-Laminat, PE, PE-Laminat bis hin zu Koex und Papier. Unsere Maschinen befüllen unterschiedliche Tubenformen: zylindrisch, oval oder konisch. Was dürfen wir für Sie abfüllen?

Komplettlösungen: Turnkey / End of Line (EOL)

Profitieren Sie von unserer Erfahrung in unterschiedlichen Branchen und in anspruchsvollen technischen Herausforderungen. Gerne stellen wir Ihnen unsere Lösungskompetenz zur Verfügung – in allen Bereichen rund um Abfüllen und Verpacken. Wir schaffen robuste Automatisierungslösungen und führen mit IWK

Turn-Key Automation ihre Produktion und Weiterverarbeitung in die Industrie 4.0.

Projektentwicklung: Ideenvielfalt für unsere Kunden

Unsere IWK Ingenieure und Projektentwickler stehen von Beginn einer neuen Herausforderung in Ihren Produktionsabläufen an Ihrer Seite. Wir richten unseren Service exakt an den Anforderungen Ihres Produktes aus und zielen damit auf eine optimale und reibungslose Sicherheit der Abläufe.

Internationaler Service: Damit Ihre Kartoniermaschine reibungslos läuft

Unsere

Tubenfüllmaschinen und Kartoniermaschinen sind auf der ganzen Welt im Einsatz. Denn unsere Expertise ist einzigartig. Davon profitieren unsere Kunden auch nach dem Kauf unserer Maschinen, weil wir uns auch dann kümmern, wenn es im Produktionsalltag zu Problemen kommt. Dazu greifen wir auf ein internationales, versiertes Netzwerk von Fachingenieuren und Technikern zurück, die bei Bedarf rasch und zuverlässig vor Ort für Sie da sind – 24/7 und in Ihrer Landessprache. Vieles lässt sich zudem über Fernwartung lösen. Wir informieren Sie gerne über unsere Wartungsverträge, mit denen Sie ein Höchstmaß an Verlässlichkeit erzielen können.

Verpackungsmaschinen für Produkte mit Anspruch

Verpackungsmaschinen im Bereich Pharma, Medizintechnik / Medical Devices

Kein Produkt ist wie das andere. Das gilt in besonderem Maße für die Bereiche Pharma, Medizintechnik und Medical Devices. Wir wissen, worauf es im Handling mit sensiblen Produkten im Medizinbereich ankommt.

Good Manufacturing Practice (GMP) ist unser Handlungsrahmen, grundlegendes Verständnis für die Bedürfnisse von pharmazeutischen Anwendungen unsere Expertise.

Spezialist für Kartonierung und Tubenfüllung unter aseptischen und sterilen Bedingungen

Setzen Sie auf den Profi: Wir sind Weltmarktführer in der Abfüllung von sterilen und aseptischen Produkten in Tuben oder Kartonagen. Der Name IWK steht für maximale Prozesskontrolle, maximale Sicherheit und kompromisslos hohe Qualität.

Verpackungsmaschinen für Kosmetik Produkte

Auf der ganzen Welt werden Zahnpasta-Tuben mit unseren Anwendungen gefüllt, verschlossen und verpackt. Wir haben die weltweit größte installierte Basis von Hochgeschwindigkeits- und Super-Hochgeschwindigkeits-Zahnpastaabfüllern – darauf sind wir besonders stolz. Auch in den Bereichen „pastöse Kosmetika“ oder „Haarkosmetik“ sind wir führend. Wir managen das Abfüllen in unterschiedlichste Verpackungen mit verschiedenen Oberflächen.

Kennen Sie den preisgekrönten Film der „

Sendung mit der Maus“ über die Frage, wie die Streifen in die Zahnpasta-Tube kommen?

Tubenfüllmaschinen – Tubenfüller mit Expertise für unterschiedliche Branchen

Vom Lebensmittelbereich über Pharma, Kosmetik und Industrie:

IWK Tubenfüllmaschinen setzen Maßstäbe.

Tubenfüller für Lebensmittel

Im Umgang mit Lebensmitteln in technischen Anlagen ist Sensibilität und Verständnis für Lebensmittelsicherheit grundlegend. Wir gewährleisten mit unseren

Tubenfüllern eine sichere Verpackung und schaffen damit die Voraussetzungen für lange Haltbarkeit.

Aseptische Abfüllung mit IWK Tubenfüllmaschinen

Unsere

Tubenfüllmaschinen sind auch dort im Einsatz, wo es besonders auf Hygiene und Sauberkeit ankommt: Beim Abfüllen in aseptischer Umgebung, um höchste Lebensmittelsicherheit gewährleisten zu können.

Unsere

Tubenfüller für den Lebensmittelbereich haben eine spezielle Abdichtung des Maschineninnenraums und lassen sich leicht abwaschen. Auch der Formatwechsel ist rasch erledigt, sowohl auf Linien als auch bei Einzelmaschinen.

Produkte mit hoher Viskosität

Besonders in der Industrie sind Produkte mit hoher Viskosität und Zähigkeit keine Seltenheit. Wir wissen auch diese abzufüllen, exakt portioniert und sicher.

Was dürfen wir für Sie befüllen?

Sprechen Sie uns an!