Of the Dutch magazine Verpackkingsmanagement and Belgian edition Packaging That’s something to be proud of and reads at least as well! Jürgen Däuwel, Area Sales Manager and with IWK for 33 years, made himself available for an interview. Jürgen talks about robotization and sustainable machine construction, our latest products, automation, industry 4.0. and success stories such as the Turnkey line for Weleda.

IWK CFC – FOKUS ON ERGONOMICS AND EFFICIENCY!

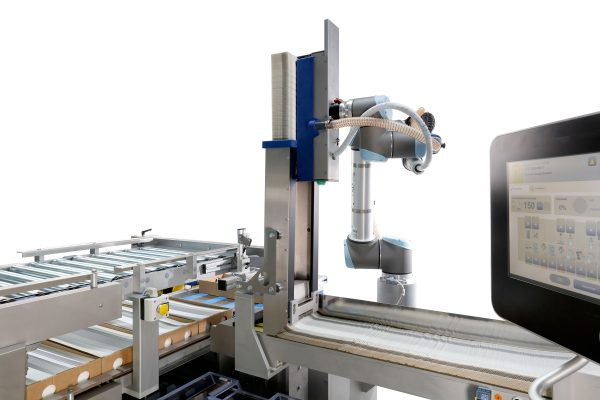

𝗢𝘂𝗿 𝗰𝗮𝗿𝘁𝗼𝗻 𝗳𝗲𝗲𝗱𝗶𝗻𝗴 𝘀𝗼𝗹𝘂𝘁𝗶𝗼𝗻 relieves the operators of simple but physically demanding tasks. The time gained can be used to ensure product quality.

Cobot systems significantly enhance the cost-effectiveness of packaging plants by providing rapid, interruption-free handling. They can be used immediately, without additional safety systems, and meet the latest industrial safety guidelines.

✚ Improved ergonomics for your employees

✚ Increased buffer (from 3 min to 15 min)

✚ Interruption-free production

✚ Format change in less than 5 min

✚ Increased workplace safety

✚ Flexible installation

✚ Easy to retrofit

UPGRADE YOUR TUBE INFEED SYSTEM!

𝗢𝘂𝗿 𝗜𝗪𝗞 𝗧𝗭𝗖 𝗳𝘂𝗹𝗹𝘆 𝗮𝘂𝘁𝗼𝗺𝗮𝘁𝗲𝗱 unloading empty tube trays from the pallet including automatic lid removal (up to 52 tubes/min). The system creates up to 1-hour buffer. No guarding is needed around the unit which gives the operator the best accessibility.

✚ High cost-efficiency

✚ Rapid amortization

✚ Interruption-free production

✚ Increased workplace safety

✚ Better handling

✚ Flexible installation

✚ Easy to retrofit

Perfect cooperation – see our cobots in action!

Check our Upgrade Catalog for more info and technical data.

CUSTOMER FOCUS – WORKSHOP AGILE SALES

𝗖𝗼𝗺𝗶𝗻𝗴 𝘁𝗼𝗴𝗲𝘁𝗵𝗲𝗿 𝗶𝘀 𝗮 𝗯𝗲𝗴𝗶𝗻𝗻𝗶𝗻𝗴.

𝗞𝗲𝗲𝗽𝗶𝗻𝗴 𝘁𝗼𝗴𝗲𝘁𝗵𝗲𝗿 𝗶𝘀 𝗽𝗿𝗼𝗴𝗿𝗲𝘀𝘀.

𝗪𝗼𝗿𝗸𝗶𝗻𝗴 𝘁𝗼𝗴𝗲𝘁𝗵𝗲𝗿 𝗶𝘀 𝗦𝘂𝗰𝗰𝗲𝘀𝘀.

Interdisciplinary project teams give their commitment to faster, more effective & more focused collaboration. And for clear goals with a focus on serving our customers in the best possible way from the beginning of a joint project to after-sales. We want a strong partnership because we know that the success of our customers is also our success!

Thanks to the team of dr. wetzel + partner Unternehmensberatung GbR for the great support!

EXPERTS FOR MULTICOLOR TUBE FILLING

𝗪𝗶𝘁𝗵 𝟭𝟮𝟴 𝘆𝗲𝗮𝗿𝘀 𝗼𝗳 𝗲𝘅𝗽𝗲𝗿𝗶𝗲𝗻𝗰𝗲 in tube filling and the largest installed base of high speed and super highspeed toothpaste fillers worldwide we are your trusted partner. Global Service with local engineers completes joint successful projects.

Whether strips, multiple layers, or swirls – contact us, we look forward to new challenges and interesting applications.

Our packaging experts will be happy to advise you sales@iwk.de

SHOWING SOLIDARITY: FLOOD CATASTROPHES IN GERMANY

It is already a tradition that colleagues from the KVP groups (continuous improvement process) regularly collect donations. Amazing 3,572 euro have been collected for the flood victims in Nordrhein-Westfalen and Rheinland-Pfalz. Many thanks also to the management, who rounded up the amount.

We support the initiative „Deutschland hilft“ with 5,000 euro!

TOPLOAD CARTONIG MACHINE IWK TL – THE STORY BEHIND OUR PRODUCT

𝗪𝗵𝗮𝘁 𝗺𝗮𝗸𝗲𝘀 𝗼𝘂𝗿 𝗜𝗪𝗞 𝗘𝗻𝗴𝗶𝗻𝗲𝗲𝗿𝗶𝗻𝗴? What is our benchmark? Which ideas are behind the development of our products? Come to our Production Site in Stutensee and discover our Topload Cartoning Machine IWK TL and the story behind the product!

paper

Kegelmann Technik x IWK. Great collaboration can be highlighted.

Especially when outstanding products are the result!

Read this interesting report in the packaging journal about Real Team Players!

PDF: Auszug aus Packaging Journal 02-03 | 2021