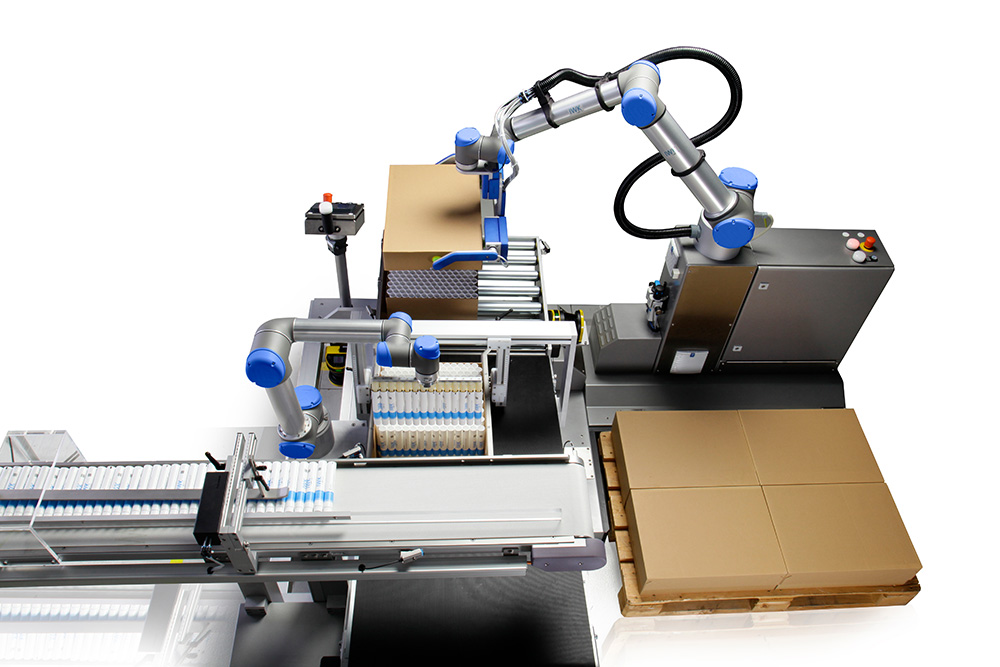

Fully-Automatic Depalletizing Cobot DPC

(up to 300 tubes/min.)

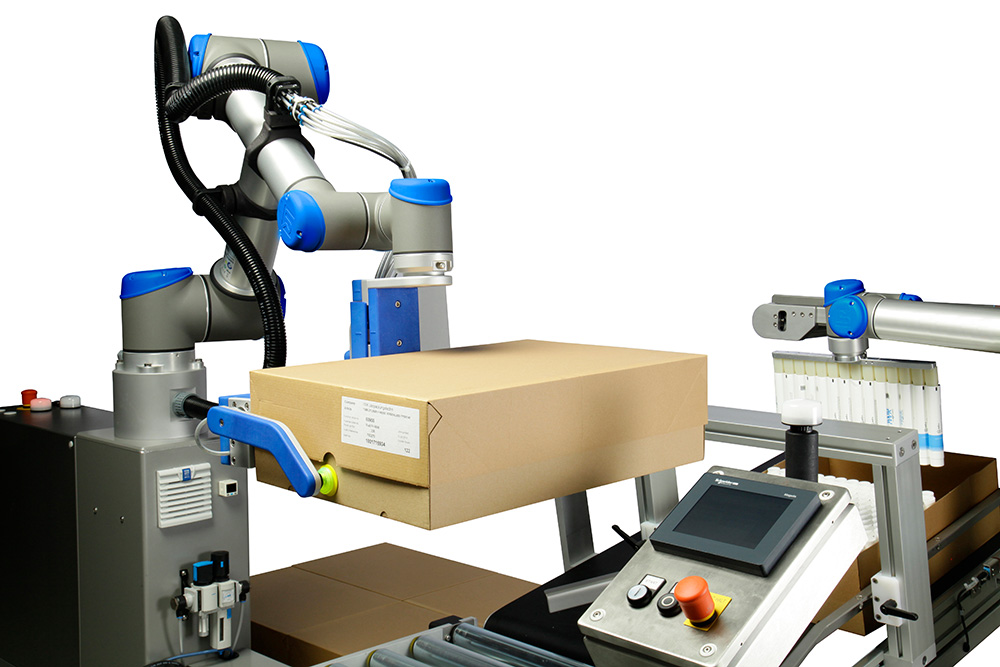

Cobot systems significantly enhance the cost-effectiveness of packaging plants by providing rapid, interruption-free handling. They can be used immediately, without additional safety systems, and meet the latest industrial safety guidelines. Retrofitting IWK cobots to existing plants is straightforward, and even installation of a single unit can be extremely advantageous and quickly pay for itself. Dependent on use, the amortization period for these systems may be as little as 12 months.

Cobot-supported depalletizing system DPC: The collaborative depalletizing system from IWK is unique in the industry and offers full equipment autonomy. A robotic arm with pneumatic gripping arms is able to access up to two pallet spaces, ensuring that the tube filling line has an uninterrupted supply. This significantly extends the cycle times between additional pallet deliveries.

ADVANTAGES

- High cost-efficiency

- Rapid amortization

- Interruption-free production

- Increased workplace safety

- Better handling

- Flexible installation

- Easy to retrofit

WORKING SAFELY

The protected zone around the tube infeed is monitored by highly sensitive safety laser scanners. Up to four scanners can register any breaches and reliably ensure protection against accidents; this satisfies the strict guidelines of the German employer’s liability insurance association, among other regulations. This intelligent system means it is possible for operators to make direct manual interventions to the tube infeed. Afterwards, the system returns to its normal production speed.

TECHNICAL DATA

| TYPE | DPC |

|---|---|

| Pallet | EURO pallet / Industrial pallet |

| TTray size (mm) | min. 200 x 200 x 70; max. 600 x 600 x 265 |

| Power ratings | 3 x 400 V/ 50 Hz |