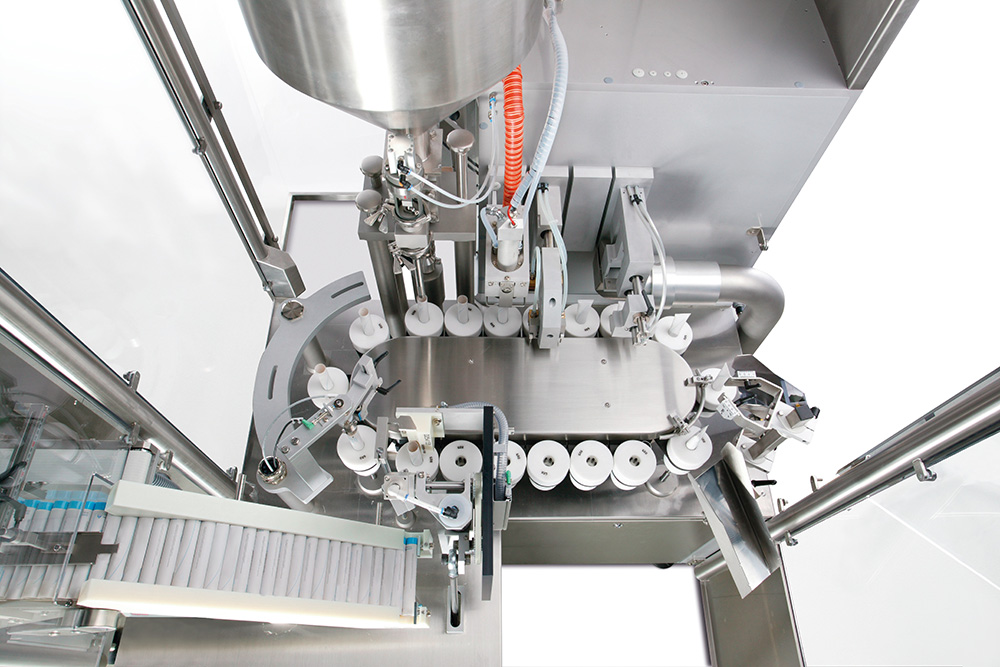

Tube Filler FP 18-1/34-1

(up to 120 tubes/min.)

Flexibility, performance and ergonomic design were the definitive development criteria for the new FP tube filling machine series from IWK. As with all machines from IWK Verpackungstechnik GmbH, this tube filler generation is synonymous with precision, cutting-edge control and drive technology, and maximum efficiency.

ADVANTAGES

- IWK quality – established over decades

- Excellent accessibility from all sides

- Maximum process reliability based on the use of servo technology

- Optimum utilization of space based on the flexible arrangement of working stations

- A robust, highly precise transport system with automatic height adjustment

- Uses a transport chain that will not stretch

- Precise positioning of tubes in the working stations

TECHNICAL DATA

| TYPE | FP 18-1 | FP 34-1 |

|---|---|---|

| Max. output (tubes/min.) | 120 | 120 |

| Number of tube holders | 18 | 34 |

| Number of filling heads | 1 | 1 |

| ø Plastic & laminate tubes (mm) | 10 – 63.5 | 10 – 63.5 |

| ø Metal tubes (mm) | 10 – 50 | 10 – 50 |

| Tube length (mm) | 60 – 250 | 60 – 250 |

| Volume (ml) | 1.5 – 700 | 1.5 – 700 |

| Small footprint, maximum accessibility, GMP design |

APPLICATIONS

Products:

Toothpaste, denture adhesive cream, pharmaceutical ointments, cream, gel, shampoo, hair dye, adhesive, dye, silicone, ketchup, mayonnaise, mustard

Tube material:

Aluminum, aluminum laminate, polyethylene, polyethylene laminate, coex

Tube shapes:

Cylindrical (with a Euro hole, curved seam), oval, conical, dispenser (dispensers, insertion of pistons), mascara pens, cartridges, jars, tottle (application of lids)