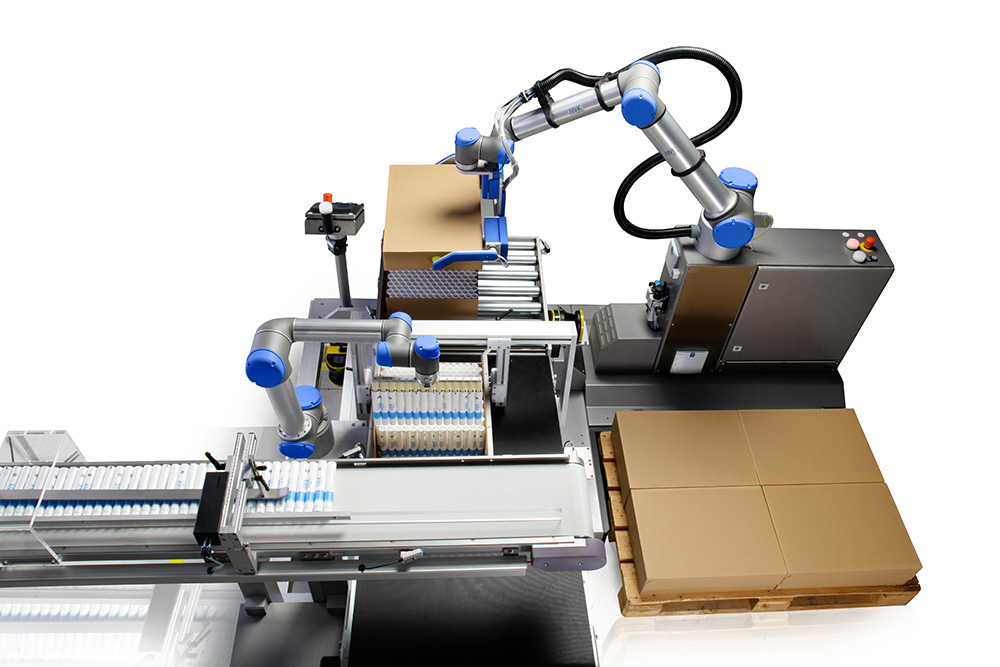

Fully-Automatic Tube Infeed Cobot TZC

(up to 300 tubes/min.)

Cobot systems significantly enhance the cost-effectiveness of packaging plants by providing rapid, interruption-free handling. They can be used immediately, without additional safety systems, and meet the latest industrial safety guidelines. Retrofitting IWK cobots to existing plants is straightforward, and even installation of a single unit can be extremely advantageous and quickly pay for itself. Dependent on use, the amortization period for these systems may be as little as 12 months.

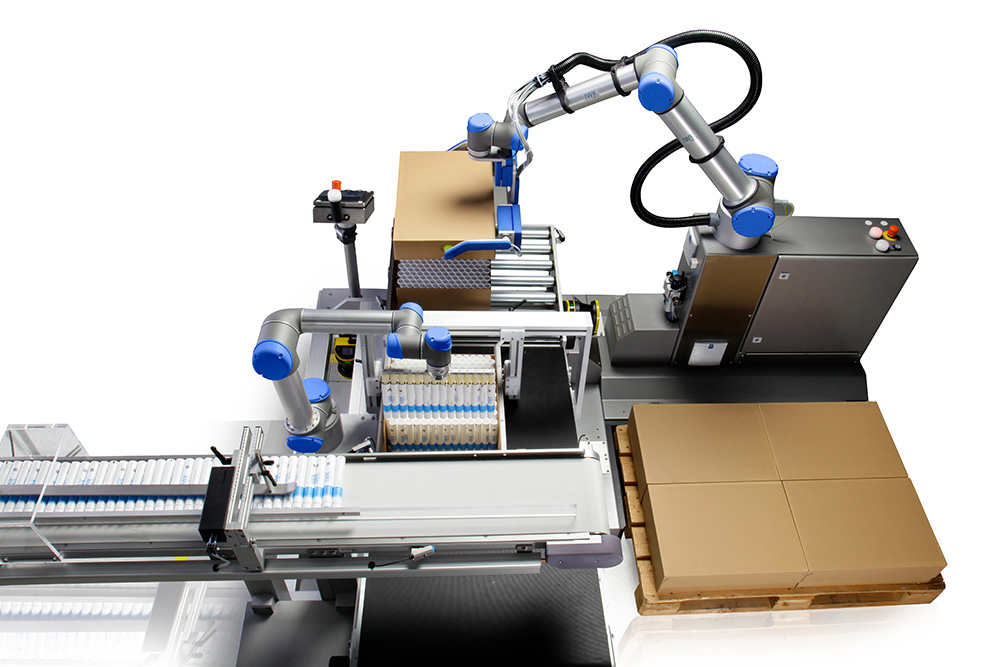

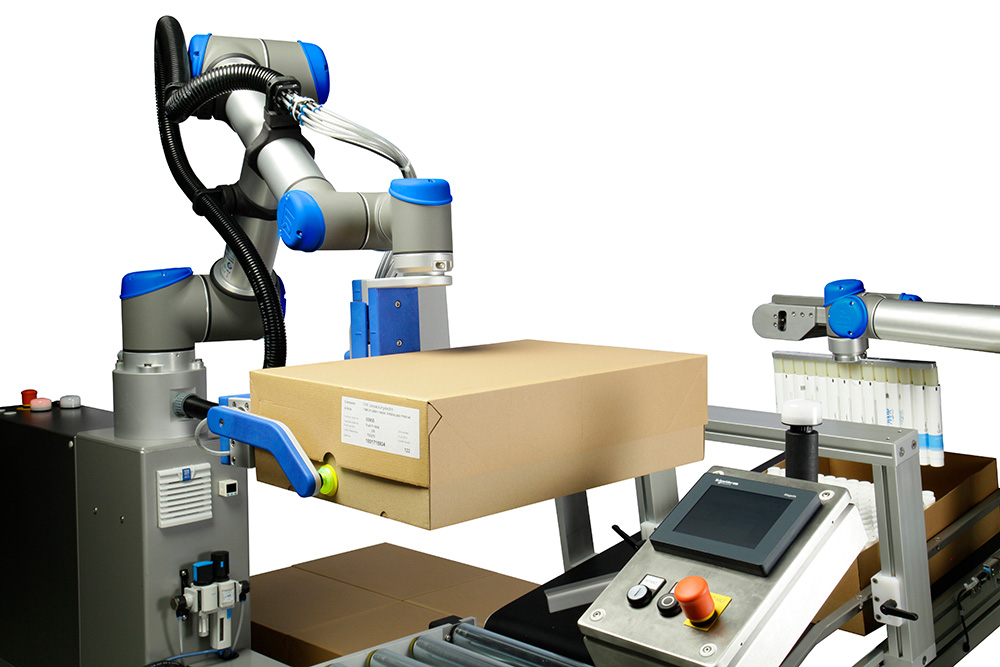

Cobot-supported tube infeed TZC: The robot arm automatically conveys empty tubes to the removal area, and lateral transport rails ensure precise positioning. As no protective housing is required, direct manual correction can be performed where necessary. A format change requires just a few simple adjustments, and the relevant parameters can be stored so they are ready to access at any time. The controls are fully integrated into the IWK system and can be easily operated using the HMI operator panel, even by users without programming knowledge.

ADVANTAGES

- High cost-efficiency

- Rapid amortization

- Interruption-free production

- Increased workplace safety

- Better handling

- Flexible installation

- Easy to retrofit

WORKING SAFELY

The protected zone around the tube infeed is monitored by highly sensitive safety laser scanners. Up to four scanners can register any breaches and reliably ensure protection against accidents; this satisfies the strict guidelines of the German employer’s liability insurance association, among other regulations. This intelligent system means it is possible for operators to make direct manual interventions to the tube infeed. Afterwards, the system returns to its normal production speed.

TECHNICAL DATA

| TYPE | TZC |

|---|---|

| Max. output (tubes/min) | 10-52 |

| Tube diameter (mm) | 50-250 |

| Total tube length (mm) | 300 |

| Power ratings | 3 x 400 V/ 50 Hz |