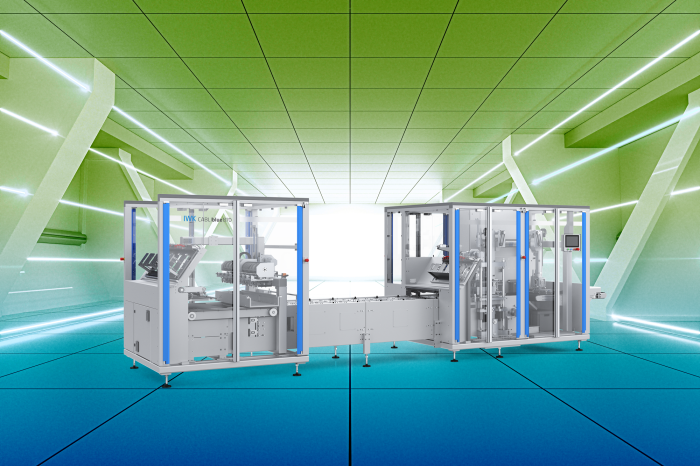

IWK Verpackungstechnik presents the energy-efficient IWK CABLIblue 870 solid cardboard blister system with high added value. The modular system focuses on sustainable solutions for many applications and enables robust packaging with high packaging volumes for medical technology, pharmaceuticals, cosmetics, DIY articles and non-food.

With nature as its co-pilot, IWK is following the global megatrend toward fiber-based packaging and reducing the use of single-use plastics in this segment. With the introduction of the new CABLIblue 870 blister system, the company sets a new standard for sustainability and efficiency in the production of 100% recyclable carton blisters and ensures a smooth transition from plastic to carton blisters. The card-to-card blister technology completes the company’s portfolio of tube filling and sealing machines, cartoners, top loaders and cobot solutions for its customers in the pharmaceutical, medical device, cosmetics, personal care and non-food industries.

Reliable card-to-card technology

The CABLIblue 870 is characterized by a high, reliable packaging output of 22 cycles per minute with, for example, 12 formats per panel, depending on the size of the blister hood and cover card. The innovative card-to-card technology makes it possible to produce robust and technically high-quality packaging that meets the high requirements for product and theft protection as well as the need for sustainable, recyclable blister packaging.

High ergonomics and added value

The engineers of the compact packaging system have designed ergonomic and open work areas that make life easier for the machine operator. Packaging material magazines are positioned for easy access and can be refilled more quickly during operation than comparable machines on the market. A universal tool-less quick-change system with clamping knobs for fixing the format parts reduces downtime. Simple “click and clamp” makes complete format changes much more efficient.

Integrated precision stepper motors instead of pneumatic cylinders reduce energy consumption. And efficient Venturi nozzles improve vacuum generation and increase the cost-effectiveness of the full carton blister system. Another user-friendly factor is the system’s very low noise level during operation.

Modular flexibility and wear-free transport

The compact and modular design of the system ensures a small footprint. The bus technology used for machine communication simplifies fast assembly, disassembly and expansion, and speeds up commissioning.

The blisters are accurately conveyed without wear and tear on the conveyor components over the life of the machine. These segments, which have been successfully installed in other packaging systems at IWK for many years, do not require lubrication. An important aspect for clean production.

A new feature for blister machines of this type is the removal, forming and transfer of the blister cap from the magazine to the transport pallet. The transfer is gentle and smooth using a screw without any additional format parts. This format-free flexibility allows a wide range of packaging options. There is a solution for almost every requirement for sustainable blister packaging.

Sustainability is a commitment

IWK is committed to recycling. The new development of the CABLIblue 870 blister system consistently pursues the requirements and goals of the closed-loop economy. The demand for high-quality, safe packaging that can be produced economically and reliably is constantly increasing. The system meets these requirements by using state-of-the-art technologies and innovative processes. Industries such as medical, pharmaceutical, cosmetics, DIY and many non-food sectors benefit from this innovation. Consumers receive more environmentally friendly products, and the environment and society benefit from the reduction of plastic waste.

The new IWK blister system combines sustainability and efficiency, making an important contribution to the ecological transformation of the packaging industry. When developing packaging for pharmaceutical and cosmetic products, it is important to choose materials that not only meet functional requirements, but are also sustainable and recyclable. The European Union’s Green Deal shows that climate and environmental protection are global social and economic megatopics. In the area of packaging, the Green Deal includes measures to prevent waste, increase recycling and use more environmentally friendly packaging materials. The aim is to promote a circular economy. The CABLIblue 870 supports the Green Deal by producing environmentally friendly packaging made from fibre-based and recyclable materials, significantly reducing the environmental footprint.

Georg Sposny, IWK Verpackungstechnik

CABLIblue 870 PDF

Read the publication in “neue verpackung” (German)