ABOUT US

Delivering excellent performance is in our DNA.

Since 1893, IWK has been synonymous with leading-edge technology for the development and production of tube filling and cartoning machines, offering outstanding performance and maximum reliability.

Our main objective is to keep our customers’ operations running with maximum productivity. To ensure we achieve this, more than 15% of our entire workforce is deployed in the areas of Pre-Sales Engineering and After Sales Service. We are currently supporting more than 10,000 systems with extremely rapid response times.

Worldwide and round-the-clock.

Expertise

We deliver state-of-the-art technology and peak quality – in each individual machine as well as each complete line system.

We have developed the expertise to do this through many years of close relationships with our customers. From these we have developed a well-founded and deep understanding of the processes involved, so we can always deliver the optimum solutions for individual requirements. This has made us the market-leader in established markets, and the top-of-mind supplier in new markets.

Corporate Culture

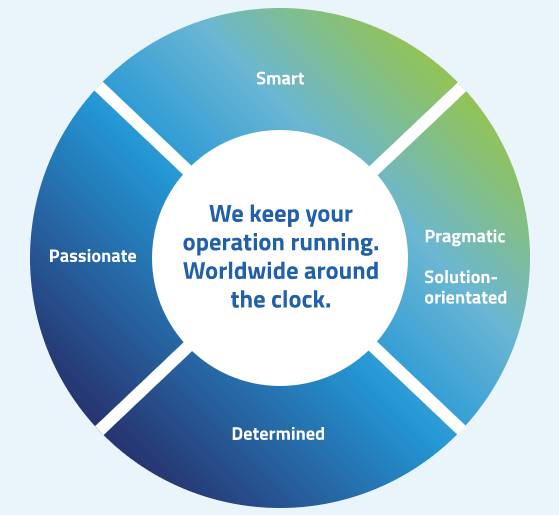

Our values are the core of our culture and they are oriented around customer needs

- Smart – we always strive for the best-engineered and most reliable solution

- Pragmatically solutions-oriented – we do as much design work as needed and search for the best solution possible

- Passionate – mechanical engineering is our passion

- Determined – we do more than just work on a job; we work for the success of our customers

- Unique – we deliver extraordinary concepts, custom-tailored solutions, and top service

ATS

With a strong partner at your side

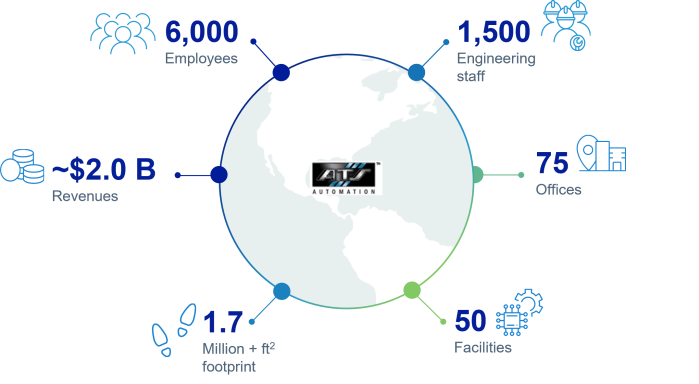

ATS Automation operates worldwide The company offers innovative and customized manufacturing solutions for many of the most successful companies in the world. ATS operates in the areas of life sciences, electronics, energy, and transport and consumer products. Industry-leading knowledge, many years of experience, and a global network form the basis for success.

ATS Automation has an established reputation for extraordinary technological solutions, and is most customers’ preferred point of contact in this area. Currently, ATS employs around 6,000 employees at 50 manufacturing facilities in North America, Europe, Southeast Asia and China.

NEWS

IWK UNDER NEW LEADERSHIP

IWK UNDER NEW LEADERSHIPAndreas Graf has taken over the management of IWK Verpackungstechnik GmbH in Stutensee, Germany, effective March 6, 2025. In his role as President of the entire IWK Group, he will be responsible for global business activities, including strategic planning and employee management. His expertise in lean manufacturing, employee engagement and business development will be instrumental in driving IWK’s continued success and innovation as a manufacturer of packaging systems for the pharmaceutical, cosmetic, food and non-food industries.

Mr. Graf has extensive knowledge as a managing director in the international packaging industry, particularly in the pharmaceutical and personal care sectors, which are also IWK’s core markets. His extensive experience in leadership, change management and strategic growth in the manufacturing and automation industries makes him the ideal candidate for this role.

With Andreas Graf, the IWK Group will further improve profitability and operational excellence and strategically expand IWK’s market position as a leading manufacturer of packaging systems.

TOPLOAD CARTONIG MACHINE IWK TL – THE STORY BEHIND OUR PRODUCT

TOPLOAD CARTONIG MACHINE IWK TL – THE STORY BEHIND OUR PRODUCT𝗪𝗵𝗮𝘁 𝗺𝗮𝗸𝗲𝘀 𝗼𝘂𝗿 𝗜𝗪𝗞 𝗘𝗻𝗴𝗶𝗻𝗲𝗲𝗿𝗶𝗻𝗴? What is our benchmark? Which ideas are behind the development of our products? Come to our Production Site in Stutensee and discover our Topload Cartoning Machine IWK TL and the story behind the product!

LOCATIONS

We are wherever our customers are – in other words we are everywhere

EMPLOYEES

“We keep your machines running,

worldwide and around the clock.”

We do not ourselves claim to be a good employer – instead, we let our employees do the talking. Just take a look at the popular employer review platforms online – you’ll be amazed.

We are proud of the strength and continuity that our experienced employees deliver. At the same time, we have many young colleagues who constantly bring new momentum to our company in different forms. And all working to the same goal: We want to deliver excellent performance!

HISTORY

We have been driven by innovation since 1893

Our focus is on enhancing production performance for customers – most of whom are in the branded goods industry – and this will continue to be the case in the future.

Whether you need first-rate production lines or machines that offer unrivaled flexibility and reliability from day one – we’ve been doing it since 1893.

IWK is well equipped for the challenges of the 21st century, and concentrates on the increasing requirements relating to system integration and multi-component packaging solutions with short lead times. In every case, with innovative solutions.

2019

IWK Thailand celebrates its 20th anniversary and triples its floor area to over 8,500 m² in the new plant.

2013

IWK has been part of the global ATS Automation Group since 2013; the group has its registered office in Canada

2007

Sale of IWK to the OYSTAR Group

1999

Establishment of the IWK Packaging Machinery subsidiary in Thailand

1979

IWK Verpackungstechnik GmbH is established, with 400 employees

Move to the company’s current location in Stutensee

1970

Merger with Kuka GmbH to become IWKA AG

1968

New development of the CARTOPAC continuous cartoning machine

1955

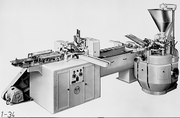

Development of the first fully automated packaging line for tubes

1949

Registration of corporate name Industrie-Werke Karlsruhe AG (IWK)

1893

Founded

PURCHASING

Partnership on an even playing field – collaborating with IWK as a supplier

Die Beschaffung von allen zur Produktion notwendigen Materialien unterliegen einem starken Wandel. Als international ausgerichtetes Unternehmen streben wir verlässliche und langfristige Beziehungen mit Lieferanten an. Grundlagen dafür sind vor allem:

The procurement of all the materials needed for production is undergoing huge change. As an international company, we strive for reliable and long-term relationships with suppliers. Above all, these are conducted on the following principle:

- IWK commits to transacting business professionally, honestly and ethically, and to complying at all times with the locally applicable laws and specifications.

- We expect loyalty and integrity from all partners involved in our activities and business relationships. Our partners can expect the same from us.

- We advocate free and fair business, without corruption, extortion, or bribery, including any illegal influencing of decisions.

- Our Code of Conduct defines the principles and requirements for our action in day-to-day business. We expect all suppliers to comply with our business practices and Code of Conduct, as well as locally applicable laws.